Corrosion Made Simple

There are three main types of corrosion, Rust. Electrolysis and Galvanic

- Rust

Rust is the most well-known form of corrosion. Most metals want to return to their natural state when in the presence of air and water. Bare mild steel will over time develop rust which looks similar to the brown-red powder of mined iron ore. Whilst the presence of rust will reduce the speed of corrosion, it will continue indefinately if not treated.

- Electrolysis

Electrolysis occurs when an electrical current strays from its path due to improper wiring. Steel boats are particularly prone to this form of corrosion as the hull is conductive and stray wires use the hull as a ground.

- Galvanic

This occurs when two different metals are in contact in the presence of an electrolyte (seawater). One metal will be more chemically active than the other and a reaction occurs.

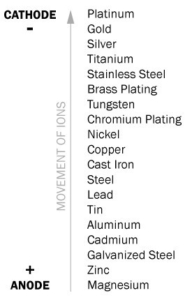

Metals can be ranked from cathodic (negatively charged electrons) to anodic (positively charged electrons). Electrons flow from the anodic metal via a conductive path (seawater) to the less chemically active metal (cathodic).

The table below shows which metals are cathodic and anodic. When two metals are in contact with each other (seawater acting as the conductor), the more ‘anodic’ metal will lose electrons to the more ‘cathodic’ metal and the anodic metal will be ‘consumed’. The distance in the chart between the two metals determines how strong the flow will be e.g. steel and cast iron will not be a major problem but zinc and steel will have a stronger flow. This is exactly why anodes of zinc are used to protect steel

Note also how high stainless steel is in the diagram – exactly why it is commonly used for boat fittings.

Controlling Corrosion

Painting

Isolating the metal from seawater by painting protects the metal and prevents corrosion. Unfortunately, in the real world, it is very difficult to get the paint to totally cover all surfaces and rust will then form in crevices.

In addition, there are a number of moving parts on a boat and it is impossible to cover all surfaces completely.

Galvanising

Galvanising is a special form of painting in that it firstly covers the bare metal with a solid

‘paint’ which prevents contact from seawater with contact with the metal. If the galvanising is not completely covering the metal, the zinc galvanising will act as an anode and prevent corrosion of the metal.

Sacrificial Anodes

Sacrificial anodes, usually made of zinc, are positioned around areas where different metals are present e.g. a stainless steel drive shaft with a mild steel hull. They are also used in engines where different metals are used in the construction of the engine.

The anodes, if working correctly, will slowly wear away and need to be checked/replaced yearly to be sure that they continue performing their function. Anodes must NEVER be painted as that reduces their efficiency.

LanoShield is a natural, environmentally friendly product that provides long lasting protection and lubrication properties to an endless variety of marine, agricultural, commercial, industrial, aquaculture, aviation, construction and many more uses. It comes in spray or grease form and creates a pressure washer, safe to 300 PSI barrier between the different metal types to stop galvanic an electrolysis corrosion. All you need is thin layer, a little goes a long way. It is also protects against salt, acid, alkaline and in non conductive

LanoShield can be purchased directly from www.lanoshield.co.uk or from our online shop.

LanoShield also has the advantage of being a fantastic lubricant and hence is also makes it perfect for nuts/bolts, shackles, machinery, hinges etc.

Note: Other Lanolin based solutions are available and would have similar properties to LanoShield

Conclusions

Each corrosion situation is different but there are a few basic rules which will reduce the effect of corrosion

- Paint all non-moving bare metal parts with a high quality paint designed for marine use or apply LanoShield. If rust does occur, wire brush and then use a product such as “Corroseal” which converts any remaining rust in the pores to a ferric oxide which is inert before repainting

- Do not, wherever possible, use two metals against each other when they are a long way from each other in the diagram above (e.g. stainless against galvanised steel)

- Use sacrificial anodes wherever different metals are in contact with each other

- Check shore power leads for correct wiring before plugging into the boat. Many marina systems have the positive and negative leads reversed and galvanic isolators fitted on boats will not normally work when polarity is reversed

- Check all wiring within the boat and ensure that all connections are secure and the insulation to all wires is not chafed of otherwise damaged